MÉTROLOGIE 3D SANS CONTACT

Machines, logiciels et services pour une mesure 3D de précision, traçable, rapide et robuste, en ligne et en bord de ligne.

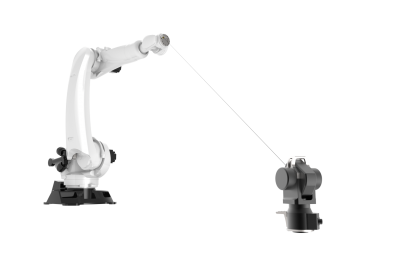

ROBOTIQUE DE PRECISION

Solutions de mesure et de calibrage pour optimiser les performances de vos processus de production robotisées

Nos services

GEOMNIA propose, en plus de sa gamme de produits, des prestations de services personnalisées.

MÉTROLOGIE 3D - ROBOTIQUE DE PRECISION

GEOMNIA possède un savoir-faire original et des compétences d'experts dans les domaines de la métrologie tridimensionnelle, du génie logiciel, de l'ingénierie de systèmes mécatroniques pour la métrologie nano et micrométrique et de la fiabilisation géométrique de procédés par mesures et logiciels.

Applications

La mesure 3D pour une production plus précise et plus rapide dans les industries.

Technologies

Plusieurs systèmes pour un même résultat : une mesure parfaite.

Ils nous font confiance

Geomnia collabore avec avec les plus grands groupes

News

All latest news about the company

Actualités

Finorpa & Siparex soutiennent…

FINORPA SCR et Nord France Amorçage (Siparex) sont intervenus respectivement à hauteur de 250 K€ et 150 K€ lors de ce premier tour de table fin 2015, pour accompagner GEOMNIA dans cette phase de développement et déploiement industriel en France et à l’International.

Actualités

Certification PTB

GEOMAX 1.0, le logiciel de métrologie GEOMNIA, a reçu la Certification du PTB (Class 1) depuis sa version de 2014. Le PTB est l’Institut National de métrologie Allemand.